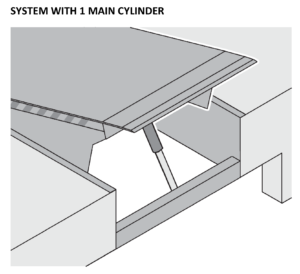

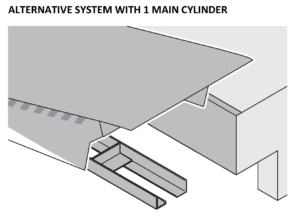

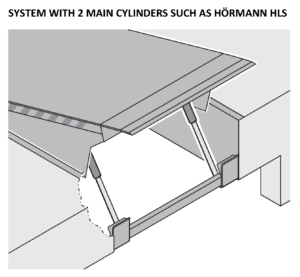

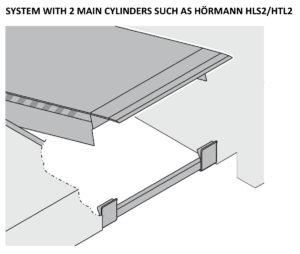

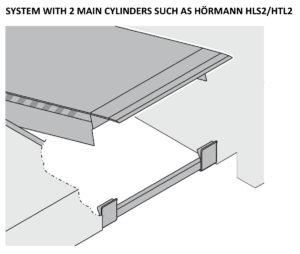

Dock levelers with one or two main cylinders is the present market norm. Hörmann’s dock levelers come with two main cylinders as this offers safety advantages in case of an emergency stop.

Both systems are comparable in their functionality.

FUNCTIONS OF THE MAIN CYLINDERS

Main cylinders are required for raising and lowering the platform. They should be chosen and positioned so that they fulfil their function well and withstand the loads. Systems with both one or two cylinders, both are fundamentally able to fulfil this function given a normal condition.

However, the real challenge arises in managing the stress on the cylinders, platform, hinges, and frame which is much higher with a one-cylinder system in the case of an emergency stop. That is due to the concentration of forces in one spot. To achieve the same level of safety, the components must be designed to be heavier. This means that if the lorry rolls or drives away, the lip is no longer supported when the platform is loaded.

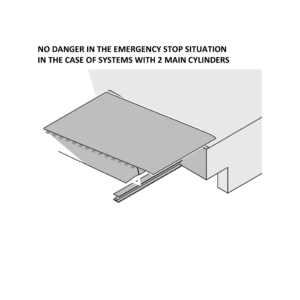

Dock levelers with one cylinder are more likely to be lopsided in the case of an emergency stop when compared to dock levelers with two cylinders. This danger exists if the weight occurs only on one side, i.e., when the forklift drives off-center. In this case, the goods could fall off the forklift. In the case of two cylinders, the hose safety devices are activated almost simultaneously. Thus, there is no lopsidedness of the platform.

Two-cylinder systems have cylinders with smaller diameters. This results in higher pressure. With two slimmer cylinders of the appropriate diameter, you can achieve the same pressure as with just one thick cylinder. The hydraulic cylinders must be matched to the total construction. As regards dimensions, the type of dock leveler, the position of the cylinders, and the hose safety device play a decisive role. This is true for both the systems.

DIFFERENCES IN QUALITY IN PRACTICE

Even more important than the choice between one or two cylinders is that hose safety devices are implemented at all points and that these are adjusted and tested. Random checks in the case of most dock levelers show that hose safety devices very often do not function at all. This is dangerous and does not conform to the EN 1398. Hose safety devices are tested every day at Hörmann to ensure absolute safety.

In addition, other factors also play a major role in deciding on a type of dock leveler construction, such as

the maximum installation height, for which the working range above or below the level should be there, where the forces should be transferred. Every manufacturer must decide for themselves which characteristics they prefer. All dock levelers must fulfil the same demands with regard to safety.

Hörmann draws on nearly 40 years of experience with the development and production of loading technology, in order to offer reliable and high-quality products. Both cylinders and hose safety devices are subject to regular tests for the sake of quality assurance.

0 Comments